Because you only have so much margin to give away.

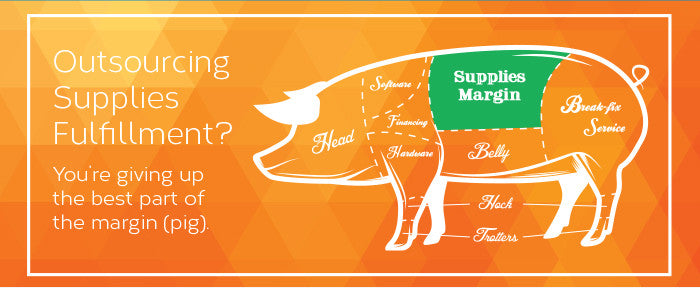

The primary reason that customers outsource the management of their printing fleet to you is because managing supplies and service themselves is hard. They have a business to run and they are not printing experts. I’ll bet your sales angle is that your dealership’s expertise is being an expert in all things printing related. You are so good at it that you can do it better and cheaper than the customer can do it for themselves. Sound like a familiar pitch? So why is your dealership considering outsourcing this function, then?No doubt that supplies fulfillment is hard, but it is a core competency of your dealership. If it is not, then it needs to be! An outsourcing company cannot outsource its core competency. If you cede this function in the value chain to another party, then you should expect your margin to dwindle. Not long ago, I was working with a large national provider and one of their OEM partners offered to outsource MPS on behalf of the provider. The reward was that the company could provide the supplies fulfillment (read: shipping and logistics) and in return the OEM would provide them with a 25% gross margin. The CEO said in the meeting: “Our company has far too many break even initiatives. We need MPS to generate profits.” Brilliant. He saw that 25% was not actually profitable. He was looking for 50%, or more, gross margin. He was being a margin pig. That’s what everyone needs to be. You need to wake up every day and think about how you can derive the most margin out of the supply chain. YOU NEED TO BE A MARGIN PIG.

Here’s another thought: your partners that are managing supplies on your behalf are using your data to generate profits! Keep in mind that when I was developing PrintFleet in 2003, my primary goal was to enable dealerships to manage their supplies. All credible RMS vendors today can track supply levels, toner coverage, and pages printed. This, along with an administrative person that can review the information on a daily basis and enter orders as they come, in is really all you need. Maybe it’s not hard, but it is tedious, and while most owners and sales people do not do tedious well, finance folks do it in spades.

Consider this:

• You have 1,000 devices being monitored

• At any given time, 100 of those devices will be at 10% toner

• In simple terms, 10 machines will enter the 10% toner threshold every day

• Entering orders for these 10 devices is a job that if you map it out properly, will take less than an hour to do

You should not need an additional employee to do this. This function scales well. If you have 8,000 devices being monitored (great problem!), well, that’s a full time job – but I am willing to bet that the cost of that employee is far less than the increase you are paying for your supplies. Another benefit here is that you have flexibility in selecting toner vendors. Your distribution partners are also trying to be margin pigs. They want more value than the single digit margins offered by toner manufacturers.

It’s up to you. Printing is a competitive business and pages are decreasing. Dealers are becoming more desperate, so they fight decreasing revenue by trying to get more market share. Margins are getting squeezed. Supplies are your biggest MPS expense.

You need to get good at this. YOU NEED TO BE A MARGIN PIG.